Compression springs

Compression springs are the most popular and widely used type of springs. They are used in all areas of our life. They are characterized by the space between the coils called the spring pitch. Compression springs have active coils, which transmits the stresses applied along the axis of the spring, and passive coils - usually located at the ends of the spring. Their function is to create two planes parallel to each other and perpendicular to the spring axis. These planes aid the spring's cooperation with other components. Thanks to the passive coils, the direction of the loading force applied to the compression spring is closer to the axis of the spring. In many cases, the end coils of springs are ground to improve this effect and increase their longevity and operating efficiency. The EN 15800:2009 standard relating to compression springs specifies the method of grinding and the deviations that can occur during this operation.

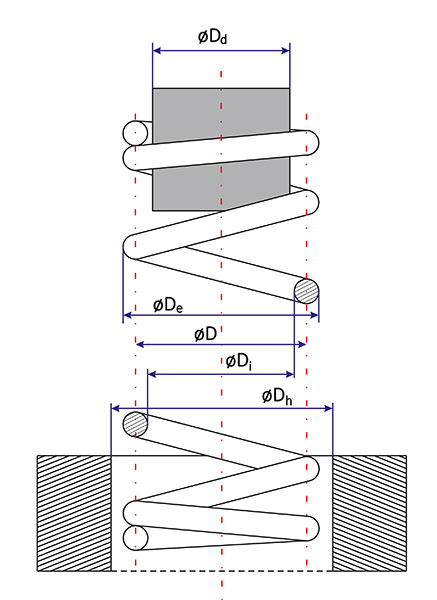

Figure. Compression springs. Ends with closed ground coils - type 1; Ends with closed coils - type 2; or without ends - unground open coils.