Springs – are fundamental elements in the construction of susceptible connections. They have two essential features: they undergo a significant elastic deformation under the influence of external load and have the unusual ability to accumulate energy in a specific volume. This feature is applied in the construction of machines. Springs perform various tasks: they accumulate energy and perform the work, relieve shock, induce shock or absorb specific damping vibrations, put pressure on kinematic pairs and are used to measure loads. Thanks to these they are widely used in almost all industries, ranging from food up to the heavy industry.

We can distinguish several types of springs depending on:

- direction and load type:

- compression springs

- extension springs

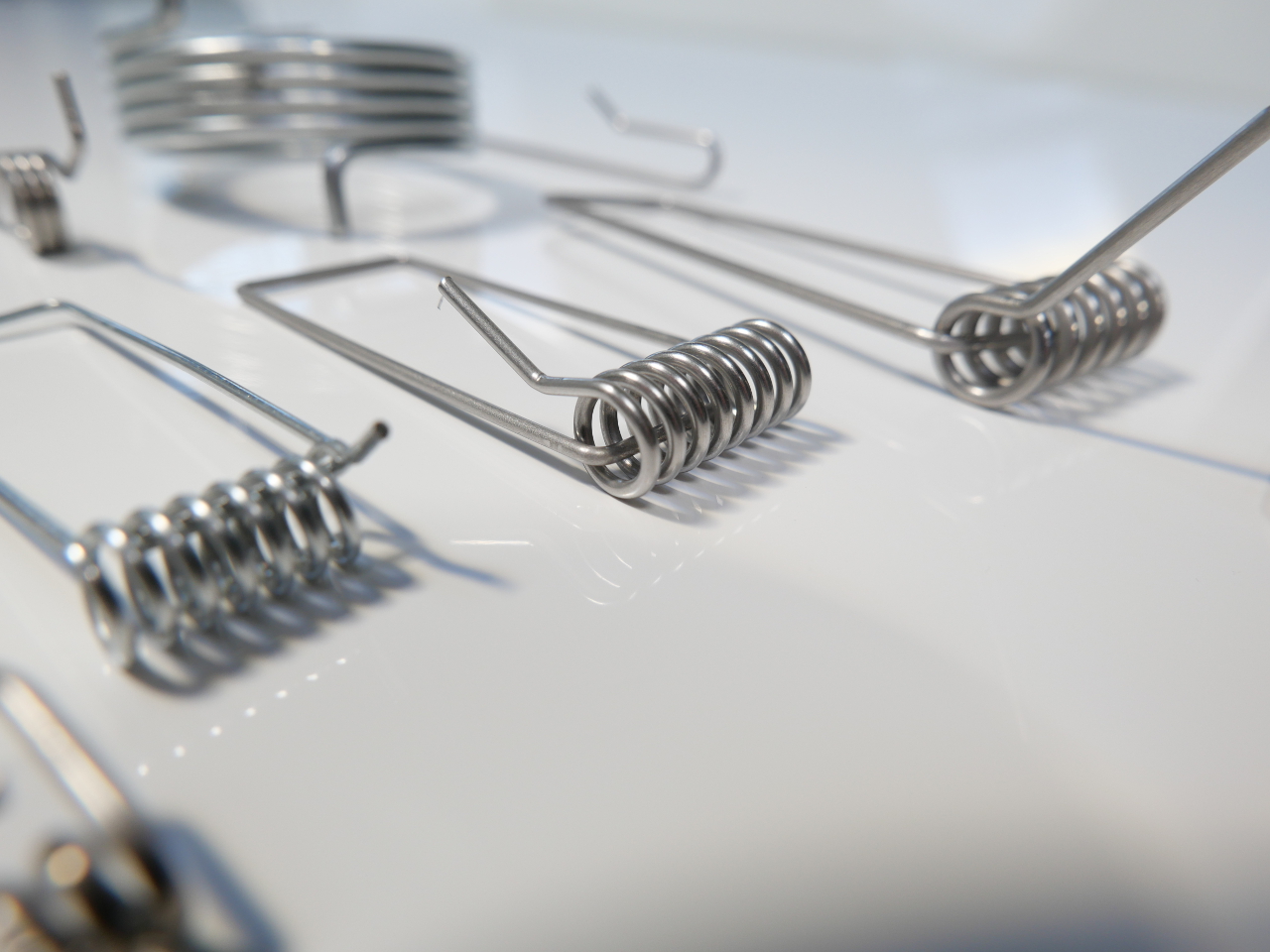

- torsion springs

ALMECH as one of the leading manufacturers of springs has in its offer springs made from the latest generation of machines for the production of CNC springs. For the production of the springs, phosphate patented wire is used – without coating, hot-dip galvanized, copper plated, covered in zinc and aluminium alloys, nickel and stainless steel. Depending on the operating environment of the spring, wires with increased resistance to high temperatures, corrosive conditions, such as acids, or with high tensile strength may be used in their production.

Fig. 11 Compression springs. With closed coil and ground ends - type 1; with closed ends - type 2; or without ends - open coils, not ground.

Special springs

The split pins we offer are made in accordance with custom-made technical drawings or detailed descriptions of the parameters. We encourage you to choose our ...

More

Torsion springs

The torsion spring available in Almech's offer is most often used in agricultural machinery, as well as in various kinds of mechanisms. We recommend high ...

More

Compression springs

Durable compression springs are renowned for their high resistance to high temperatures, as well as to harmful external factors. We encourage you to choose our ...

More

Extension springs

Extension springs available in our offer are most often used as components in sofas, but also in automobiles. Welcome, If you are interested in good ...

More